Manufacturing service

In-House Manufacturing, Engineered for Precision and Scale

We take full control of the manufacturing process—because that’s how we ensure performance, quality, and delivery, every time.

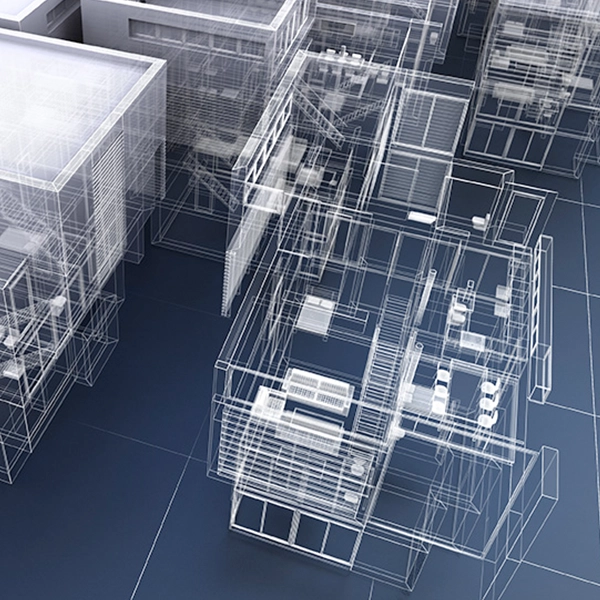

Our operations are centered in a state-of-the-art, 215,000 sq. ft. facility, meticulously designed around Lean production principles. Every square foot is optimized for efficient flow, safety, and quality—allowing us to deliver complex façade systems with speed and consistency.

why choose us for

Manufacturing

High-performance production starts with strategic planning.

Using a proprietary Capacity Planning Tool, we forecast and manage shop workloads up to 24 months in advance—enabling us to align production with project timelines, respond to field-driven changes, and secure long lead-time materials early through close collaboration with supply chain partners.

This forward-looking approach allows us to stay nimble in the face of shifting jobsite conditions—without sacrificing quality or speed.

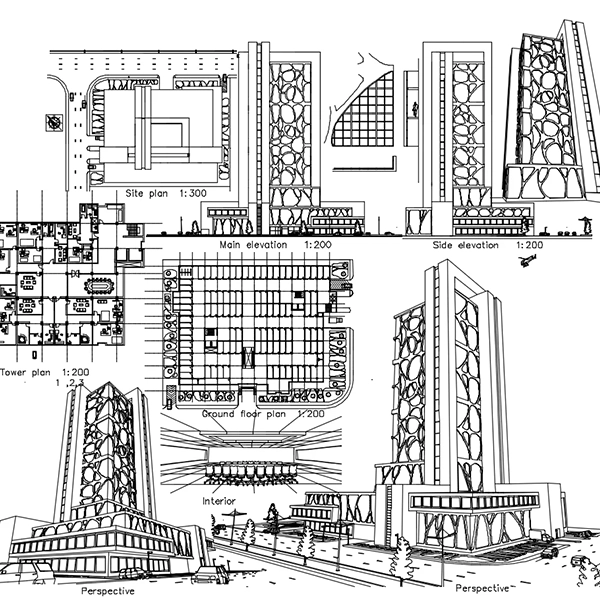

Seamless Flow from Design to Fabrication

Our custom-built Release Management System bridges engineering and production with precision. It extracts all relevant data from our design tools—units, sub-assemblies, parts—and organizes them into optimized work orders for fabrication.

It also auto-generates detailed shop floor documentation, enabling smooth progression from cutting to assembly to field delivery—all in the exact order required.

Quality in Every Step. Predictability in Every Outcome.

Our manufacturing process is not just built for output—it’s built for excellence. Every part of our workflow—from planning to production—is driven by discipline, expertise, and a commitment to quality. That’s how we consistently deliver on the promises we make:

Advanced Technology Meets Experienced Craftsmanship

Inside our production facility, you’ll find:

From standard units to highly customized assemblies, our team delivers repeatable, reliable results—built to spec, built to last.